Activated carbon

Activated carbon is a black, odorless, tasteless solid that refers to a type of carbon that has a porous structure, small pores, and a high internal surface area.

Activated carbon is a unique material used in adsorption processes as a strong adsorbent for soluble substances in gases and liquids or chemical reactions due to its high internal area, porous structure, high adsorption capacity, surface reactivation capability.

Activated carbon is obtained from the pyrolysis or carbonization of cellulosic materials such as wood, coal, fruit shells such as hard coconut shells, walnuts,

almonds, pistachios, hazelnuts, or the kernels of fruits such as peaches and apricots and in the next steps, these substances are activated physically or chemically.

Pyrolysis of cellulosic materials, in the absence of air, destroys inorganic molecules and removes them from the cellulosic material, resulting in the formation of a carbon solid. The materials produced have a high special surface and high porosity.

Application of activated carbon for the absorption of impurities:

Many liquids and gases contain some impurities. In some cases, these impurities include microbes, bacteria, toxins, and other contaminants that, despite their very small percentage, actually create adverse conditions that change the taste, odor, color, and other properties of the liquid or gas. For achieve the desired conditions in such liquids and gases, impurities must be removed.

One of the effective methods to remove impurities is their removal by adsorption method. Activated carbon is a strong adsorbent material with excellent surface adsorption that is used to remove impurities. Activated carbon does not dissolve in any known solvent, and its most important property is the selective removal of

pollutants. The rate of adsorption of impurities on activated carbon depends on the size and structure of the pores, the pore size distribution, as well as the size and shape of the impurity molecules.

The adsorption phenomenon on the pore surfaces of activated carbon is due to the unbalanced energy between the surface electrons and the internal electrons of the pore surfaces. This energy is generated by the molecular attraction of van der Waals due to the breakdown of the carbon-carbon (C-C) bond. The inner surface of the pores of activated carbon adsorbs the impurity molecules and the energy balance is established.

Activated carbon application

Depending on the raw material used in the production of activated carbon and its production method, several types of activated carbon are produced for use in various industries. The most common use of activated carbon to absorb impurities is in the following industries:

- Water and wastewater treatment industries to remove unwanted color, odor and taste from water (remove chlorine, bacteria)

- Treatment of wastewater containing biological, bacteria and hazardous substances (reduction of BOD and COD)

- Gas refineries for gas sweetening,

- Oil refineries and petrochemicals

- Gold processing and extraction industries

- Drug production industries and for drug purification

- Sugar production industries to remove dyes (decolorating) and impurities

- Industries producing edible and industrial oils,

- Power plants

- Air pollutants industries to absorb pollutants

- Equipment for purification and filtration of air and gas pollutants from factory chimneys

- Recycling of organic solvents and chemicals

- The basis of chemical reaction catalysts in the oil and petrochemical industries (sediment of metals, mineral salts and organic matter on the wall of activated carbon pores)

Properties of activated carbon:

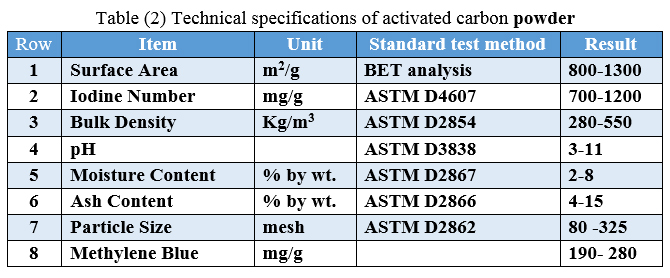

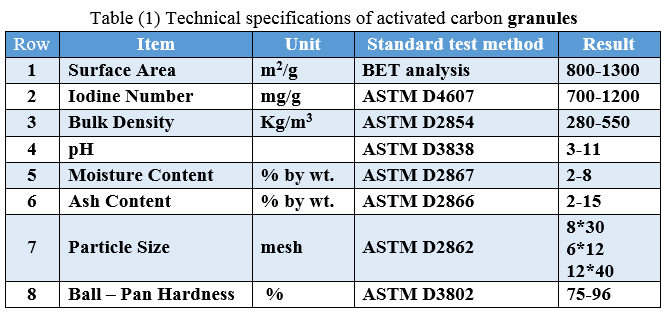

Considering the wide range of activated carbon consuming industries, the variety of impurities that must be adsorbed by activated carbon from different materials in these industries, and the variety of sources of cellulosic raw materials for production, Shimi Pajoohan Co. produces several types of activated carbon with special physical and mechanical properties required by consumer industries.

Shimi Pajoohan Co. take place the necessary tests to determine the physical properties of activated carbon in the company’s laboratory using the necessary equipment, devices and ASTM standard methods. The following are the physical characteristics that are important for selecting the type of activated carbon;

- Specific Surface Area, BET

- Porosity

- Pore size

- Particle Size

- Hardness

- pH

- Density

- Iodine Number/Adsorption

- Ash Content

- Methylene Blue

- Moisture Content

Since product quality control is very important, Shimi Pajoohan Co. take place the necessary tests to determine the properties of activated carbon at the production site and in its laboratory.

Shimi Pajoohan Co., based on the needs and orders of consumers, produces activated carbon in two forms of granules (irregular grains) and powder with the following specifications;

Packing type:

• Waterproof bags 15 to 20 kg

• Jumbo bag 400 to 500 kg/p>