Graphite Parts and Raschig Rings

Amorphous carbon turns to graphite under certain conditions (heat and pressure). Graphite is an allotrope of carbon composed of layers of carbon atoms formed from the transformation of plant material. These layers make graphite slippery and greasy. Hence graphite becomes a very soft mineral. Graphite has a dark gray color and shiny metal. Graphite has a high thermal and electrical conductivity. At very high pressures and temperatures, carbon layers stick together and graphite turns into diamonds. This process is actually how to produce synthetic diamonds.

Crystallized forms of carbon, namely graphite and diamond, have two different properties. Graphite is the softest material and diamond is the hardest material.

Carbon, graphite and their composition and mixture with other materials, according to the properties they can create, are used in most industries, especially oil, gas and petrochemical industries, chemical industries, polymers and food.

Graphite products of Shimi Pajoohan Co.

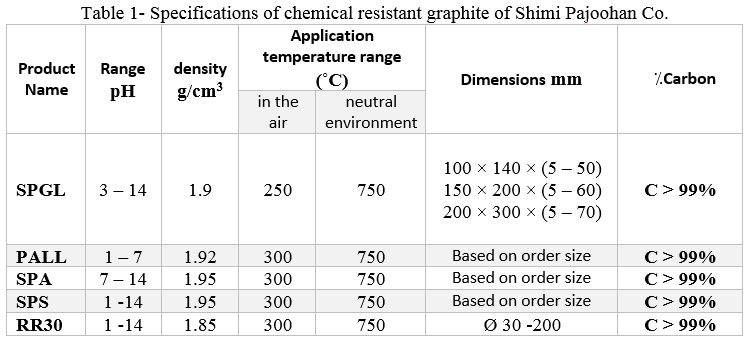

1- Chemical resistant graphite block, parts and granules

Graphite is used in the reaction medium in most chemical industries, such as petrochemical industries, refineries, and acid factories. This type of graphite is used as catalysts or a base for catalysts and creates a large contact surface that increases the speed of reactions.

Chemical-resistant graphite are made as block for wall of reactors, as simple floating lump, and as cylinders or rings of various dimensions called Raschig Rings.

The purity of carbon in Chemical-resistant graphite produced by Shimi Pajoohan Co. is about 90% to 99.9%. This type of graphite is resistant to strong acidic and alkaline environments (pH = 1-14).

Based on the customer’s order, Shimi Pajoohan Co. has produced chemical resistant graphite and in some cases has succeeded in simulating their foreign samples.

This company is ready to provide any advice in choosing the type of graphite required by the consumer industries of this product.

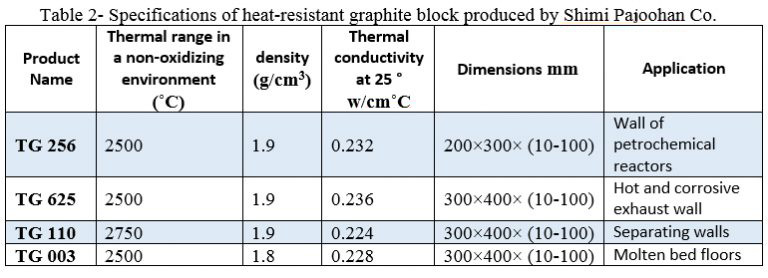

2-Heat resistant graphite block

In some industries where corrosive gases or high heat gases are used, transfer lines or equipment walls are selected from carbon and graphite.

Shimi Pajoohan Co. produces heat-resistant graphite block with different dimensions and thicknesses according to the customer’s order. The high specific gravity of these parts and block causes rapid heat transfer. Also, the shape of graphite grains in these parts and block is non-flaky and is formed by isostatic press and microscopic sheets in graphite are not directional. The bond in this type of coating is more than carbon-graphite and carbon-carbon.

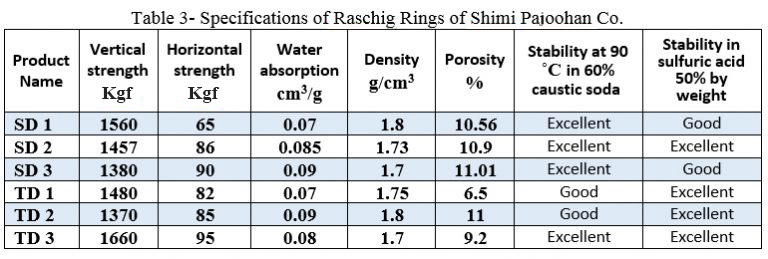

3-Carbon and graphite filler parts (Raschig Rings)

Filler rings or cylinders called Raschig Rings are used in towers where the liquid phase and the gas phase are in contact with each other to create high contact surface between the two phases. Carbon and graphite filler parts do not participate in the reaction and only increase the contact surface and two-phase contact time to increase the reaction efficiency.

Carbon and graphite filler parts (Raschig Rings) are used as tank fillers, adsorption and distillation towers in oil and gas units, and acid and base concentrators.

Shimi Pajoohan Co. produces and supplies carbon and graphite filler parts in different shapes and sizes of cylindrical and semi-cylindrical, rectangular and polygonal.

Carbon and graphite filler parts can be produced with an inner diameter of up to 90 mm and a height of up to 200 mm. Also, special shapes are produced on request.

4-Graphite blocks and flow metal graphite

Carbon and graphite brushes are used in electric motors and generators to provide electrical current during contact between the external circuit and the coil.

The characteristics of the flow block used in the broom are as follows:

- Electric current conductor

- Low electrical resistance

- Mechanical strength in dealing with the switch surface

- Do not create sparks

- No abrasion and friction

Shimi Pajoohan Co. produces flow blocks in three groups:

1- Carbon-graphite bond blocks are of G and FT type (carbon-graphite bond block are usually used in brushes that have low speed and low flow),

2- Blocks with resin-graphite bond are of SHB and NF type,

3- Metal-graphite blocks (according to the customer’s order and with different types of metals, copper – graphite, aluminum – graphite and… with different percentage).